Ce este tehnologia sistemului de sablare cu CO2 Rock?

Product Link:

Understanding CO2 Rock Blasting System Technology

The CO2 Rock Blasting System Technology was developed as a safer and more controlled alternative to traditional explosive-based rock blasting. This technology leverages the phase transition of liquid carbon dioxide (CO₂) from its liquid state to gas, releasing energy that fractures rock formations. Unlike conventional explosives, which rely on chemical reactions that can be unpredictable and hazardous, the CO₂ system offers a more controlled and environmentally friendly approach to rock breaking.

How Does the CO2 Rock Blasting System Work?

The CO₂ Rock Blasting System involves several meticulously coordinated steps to ensure effective and safe rock fragmentation:

Site Survey and Planning

Engineering Assessment: Engineers conduct a thorough survey of the blasting site to assess geological conditions and determine the optimal locations for drilling holes.

Drilling Plan: A detailed drilling plan is created, specifying the positions and spacing of each hole to ensure uniform rock fragmentation.

Equipment Delivery and Setup

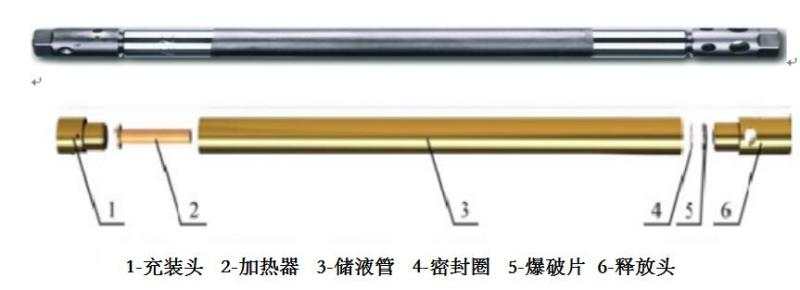

Transporting Equipment: The entire blasting setup, including rock splitting tubes filled with heating elements, gas filling tanks, and connecting pipes, is transported to the quarry or tunnel site.

Installation: Engineers install the equipment, ensuring that all components are correctly positioned and connected.

Drilling Holes

Targeted Drilling: Based on the drilling plan, holes are drilled into the rock formation. These holes are strategically placed to maximize the efficiency of the blasting process.

Inserting Rock Splitting Tubes

Placement: Rock splitting tubes, which contain heating elements, are inserted into the pre-drilled holes.

Connection: Each tube is connected to the gas filling tank via gas connecting pipes.

Filling with Liquid CO2

Gas Filling: Liquid carbon dioxide is carefully introduced into each rock splitting tube through the connected pipes.

Pressure Regulation: The liquid CO₂ is filled until the pressure within the tube reaches the designated level, ensuring adequate energy release upon phase transition.

Securing the Site

Backfilling: After filling, the holes are backfilled with soil to stabilize the tubes and prevent accidental displacement.

Flyrock Management: Protective barriers are set up to contain any unintended rock fragments, enhancing site safety.

Evacuating Personnel

Safety Protocols: All personnel are evacuated to a safe distance to prevent injuries from potential flyrock or shock waves.

Initiating Rock Blasting

Controlled Release: Using a controller, engineers initiate the rock blasting process. The heating elements trigger the rapid expansion of liquid CO₂ into gas, releasing energy that fractures the rock.

Advantages of CO2 Rock Blasting System Technology

The CO₂ Rock Blasting System offers several benefits over traditional explosive methods, making it a preferred choice in specific applications, particularly in tunnel blasting.

Enhanced Safety

Reduced Risk of Accidental Detonations: Unlike traditional explosives, the CO₂ system does not involve sensitive explosive materials, significantly lowering the risk of accidental detonations.

Controlled Energy Release: The phase transition of CO₂ allows for a more predictable and controlled release of energy, minimizing the chances of flyrock and excessive shock waves.

Environmental Friendliness

Minimal Harmful Emissions: The primary byproduct of the CO₂ system is carbon dioxide, which, while a greenhouse gas, is managed within the system to minimize environmental impact. This contrasts with the toxic gases released by traditional explosives.

Reduced Ground Vibrations: The controlled energy release results in lower ground vibrations, reducing the environmental footprint and minimizing disturbance to surrounding areas.

Operational Efficiency

Uniform Rock Fragmentation: The precision of the CO₂ system ensures that rock is fragmented uniformly, enhancing the efficiency of material handling and processing.

Adaptability in Tunneling: The CO₂ system is particularly advantageous in tunnel blasting, where the confined environment poses significant risks when using traditional explosives.

Simplified Logistics

Easier Transportation and Storage: The absence of flammable chemicals simplifies the transportation and storage of CO₂ blasting systems, as they are classified as conventional cargo.

Lower Regulatory Hurdles: With fewer restrictions compared to traditional explosives, obtaining permits for CO₂ rock blasting is generally more straightforward, accelerating project timelines.

CO2 Rock Blasting in Tunnel Applications

Tunneling presents unique challenges for rock blasting due to the confined spaces and the proximity to sensitive infrastructure. Traditional explosives in such settings can lead to excessive flyrock, ground vibrations, and harmful gas emissions, making them unsuitable for many tunneling projects. The CO2 Rock Blasting System Technology offers a safer and more controlled alternative, making it ideal for tunnel blasting applications.

Why CO2 Rock Blasting is Preferred in Tunnels

Enhanced Safety: The controlled energy release reduces the risk of flyrock and minimizes the impact of shock waves, ensuring the safety of workers and the integrity of nearby structures.

Environmental Compliance: Lower emissions and reduced vibrations help quarries and tunneling projects comply with stringent environmental regulations.

Operational Flexibility: The ability to perform effective blasting in water-filled or high-temperature holes makes the CO₂ system versatile for various tunneling conditions.

Real-World Applications

Several tunneling projects worldwide have successfully implemented the CO₂ Rock Blasting System, demonstrating its effectiveness and safety. These projects have reported fewer accidents, better compliance with environmental standards, and enhanced operational efficiency compared to traditional explosive methods.

Case Study: Safe Blasting in Urban Tunnels

In an urban tunneling project, the use of traditional explosives posed significant risks due to the proximity of residential buildings and underground utilities. By adopting the CO₂ Rock Blasting System, the project achieved controlled rock fragmentation with minimal flyrock and reduced ground vibrations. This not only ensured the safety of nearby residents but also streamlined the permitting process, allowing the project to proceed without major delays.

Conclusion

The CO2 Rock Blasting System Technology represents a significant advancement in rock blasting methods, offering a safer and more controlled alternative to traditional explosives. Its application in tunnel blasting has proven particularly beneficial, addressing the unique challenges posed by confined environments. By mitigating the inherent risks of traditional explosives and providing superior control and precision, the CO₂ system enhances both operational efficiency and safety.

As the quarrying and tunneling industries continue to prioritize sustainable and safe rock-breaking methods, the adoption of CO₂ Rock Blasting System Technology is likely to increase. This innovative technology not only improves operational outcomes but also contributes to the overall well-being of workers and the environment, setting a new standard for rock blasting practices.

For quarry and tunneling operators seeking to enhance safety, comply with environmental regulations, and improve operational efficiency, the CO2 Rock Blasting System Technology offers an effective and forward-thinking solution.